Location -> News

News

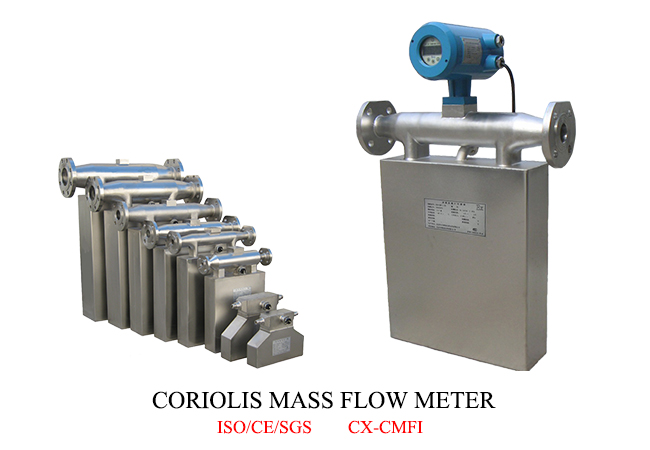

Coriolis Mass Flow Meter for Limestone Slurry Density Measurement

sales01@cxflowmeter.com

Due to the corrosiveness and abrasiveness of the slurry in the desulfurization system, as well as the high solid content (up to 30%), the density of the slurry cannot be measured by conventional test methods, which limits the selection of density meters.

Due to the corrosiveness and abrasiveness of the slurry in the desulfurization system, as well as the high solid content (up to 30%), the density of the slurry cannot be measured by conventional test methods, which limits the selection of density meters.

There are three main methods for measuring slurry density in desulfurization system, namely differential pressure method, γ-ray radiation absorption measurement method and Coriolis force mass flowmeter method.

Coriolis mass flow meters measure the density of limestone slurries in desulfurization systems because the structure of the flow meter is similar to a vibrating tube density meter. The measuring tube vibrates continuously at a certain resonant frequency. Because the resonant frequency is a function of fluid density, the vibration frequency of the vibrating tube also changes when fluids of different densities fill the vibrating tube.

Therefore, the frequency change of the vibrating tube is measured to complete the density measurement. This method is currently the mainstream measurement method of slurry density. The method is accurate and reliable in measurement and adapts to a wide range of slurry density. It can fully meet the requirements of on-site use. In order to use this product better, the following aspects should be paid attention to.

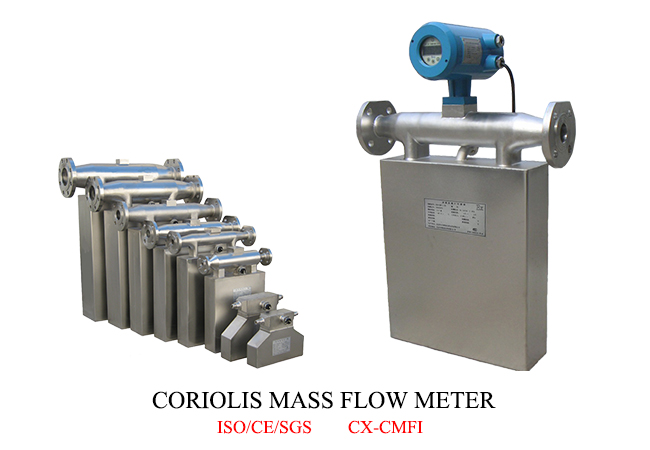

1: When installed vertically or horizontally, the measuring tube should be facing upwards to protect the measuring tube from the frequency change of the measuring tube caused by the accumulation of solid residues, thus affecting the accuracy of its density measurement.

2: When using a Coriolis mass flowmeter to measure density in the field, the flow or the effect of flow on the mass flowmeter is often ignored. The flow of the medium flowing through the mass flowmeter has no direct effect on the density measurement accuracy of the flowmeter, but the high-speed flowing limestone slurry wears the measuring tube of the mass flowmeter greatly, thus affecting its service life.

Therefore, the flow rate through the mass meter should not be too high to increase its service life and reduce costs. The specific method is that if the flow of the main pipeline is too large, a mass meter can be installed in the bypass to control the flow through a valve.

3: Do not install directly on the outlet of the vertical exhaust pipe, but on the pressure side of the pump (to prevent low pressure).

4: After long-term use, due to material accumulation, wear and corrosion, the mechanical structure of the measuring tube has changed, and its resonance frequency is affected by these factors, resulting in a decrease in the accuracy of density measurement, which must be recalibrated and adjusted on site.

5: Before long-term use, rinse the pipe with clean water to prevent limestone from adhering to the wall of the measuring pipe, or even blocking the pipe, resulting in a decrease in measurement accuracy or even inability to measure.

The differential pressure method is an indirect measurement method, that is, the pressure difference between different heights of slurry is measured by a differential pressure transmitter, and the slurry density is calculated according to ρ=P/gH, where ρ is the slurry density, and P is the differential pressure. transmitter. Output pressure, H is a fixed distance, and g is a constant.

The main advantage is that it is inexpensive and does not require a separate measuring piping system. However, the measuring probe is easy to be blocked, and the instrument data remains unchanged in severe cases, and the monitoring function is lost. In addition, the measurement accuracy is low. The reason for the deviation is that the density of the slurry is not uniform at each point.

If you want to know more about Coriolis flowmeter related parameters and quotation, please contact winny:sales01@cxflowmeter.com

If you want to know more about Coriolis flowmeter related parameters and quotation, please contact winny:sales01@cxflowmeter.com

Last:Matters needing attention when .. Next:Main common problems and analys..